Corrugating Roll not only directly determines the quality of corrugated cardboard, but is also one of the most frequently replaced and expensive components of the corrugated cardboard production line. It is called the "heart" of the corrugated cardboard production line.

When the corrugating roller is working normally, the operating temperature of key parts is above 180°C, and the instantaneous temperature can reach above 230°C.

Exposed to environments with high temperatures, heavy loads, and water vapor for long periods of time.

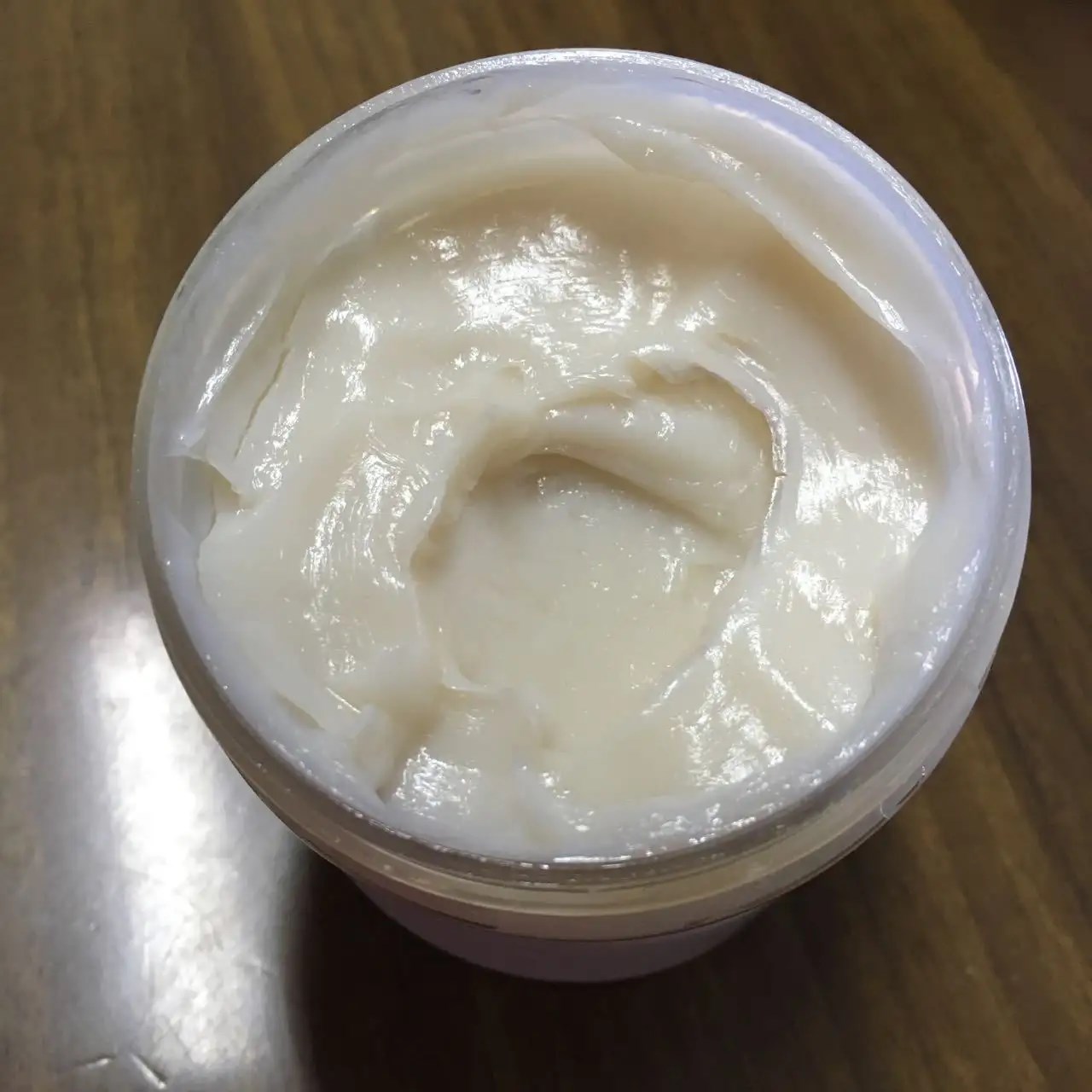

Therefore, it is necessary to use Single Facer grease to lubricate and protect the equipment from corrosion.

Many grease manufacturers on the market use high dropping points as a promotional tool, claiming that the temperature resistance is as high as 300°C or higher, but various problems often occur during actual use.

Because the grease at the corrugated roller has been in a high-temperature state for a long time and is subject to shearing, it often has a tendency to decrease in consistency and easily coke.

Therefore, the use of grease cannot only focus on temperature as an indicator but requires comprehensive consideration for long-term use.

Common lubrication failure points in corrugated product production lines

1. Grease precipitation-oil flow

The specific performance is: that the consistency of the grease becomes thinner and flows out from the bearing.

Reason: The grease cannot withstand high-temperature conditions and shearing environments for a long time. The soap base structure in the grease is destroyed, and the oil soap separates, so it softens and is lost.

2. Grease carbon deposit-coking

Specific manifestations include severe bearing wear or direct locking, similar to dry friction.

After opening the bearing, it was found that the grease no longer existed in a semi-fluid state, but was replaced by black carbon deposits.

Reason: The oily substances that play a lubricating role in grease undergo chemical changes such as oxidation at high temperatures. Long-chain molecules are broken into short-chain molecules and eventually become carbides.

3. Insufficient lubrication capacity and stuck

The specific manifestation is: that during regular maintenance, there is semi-fluid grease on the bearing, but the bearing is severely worn.

Reason: The grease has insufficient lubrication capacity and cannot form boundary lubrication or extreme pressure lubrication during friction.

This means that the grease has no lubrication effect or has a limited effect, the bearings are still in direct contact and friction occurs.

In view of the fact that the corrugating roller has been in a working environment of high temperature, high load, and presence of water vapor for a long time, in order to ensure its long-term operation and reduce downtime, the grease used should meet the following requirements:

1. High-temperature resistance: It can work under at least 200℃ for a long time without loss.

2. Anti-oxidation: Good oxidation stability. When the lubricant comes into contact with air in a high-temperature environment, it will not be oxidized quickly to form oxides and avoid the formation of carbides.

3. Water vapor resistance: Grease will not emulsify or hydrolyze when exposed to water.

4. Shear resistance: When the grease is subjected to shear for a long time during mechanical operation, the soap fibers will separate and flow, and the grease structure will be unstable, resulting in a decrease in consistency.

The perfluoropolyether high-temperature grease series developed by HUATAO has good performance at high temperatures and has a long service life. It meets the usage environment of corrugating machine equipment and has mature application experience. Welcome to call us for consultation and free sampling.